CP1

Overview

CP1 is an Aluminum-Iron-Zirconium powder solution designed specifically for additive manufacturing using laser powder bed fusion (L-PBF). This material brings multiple advantages including high strength & ductility, excellent thermal/electrical conductivity, high productivity LPBF processing and simplified post-processing.

Surface finishing:

– Chemical polishing

– Decorative anodising (type II)

– Hard anodising (type III)

Corrosion performance:

– Excellent corrosion resistance: AHEADD CP1 outperforms conventional alloy systems in corrosion performance due to rapid solidification microstructure.

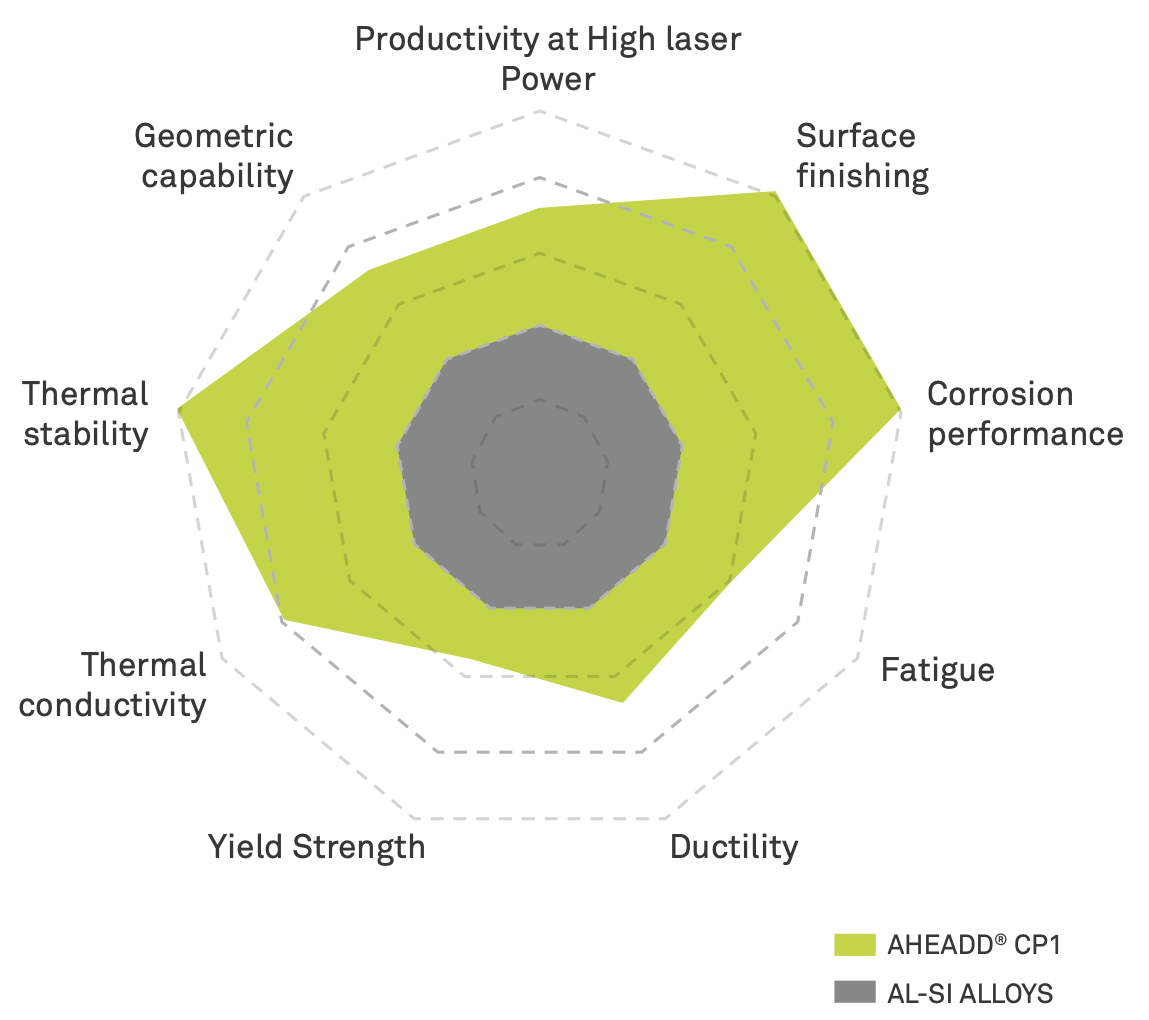

The following diagram shows the summary of comparison between CP1 and Al-Si alloys.

Powder characteristics

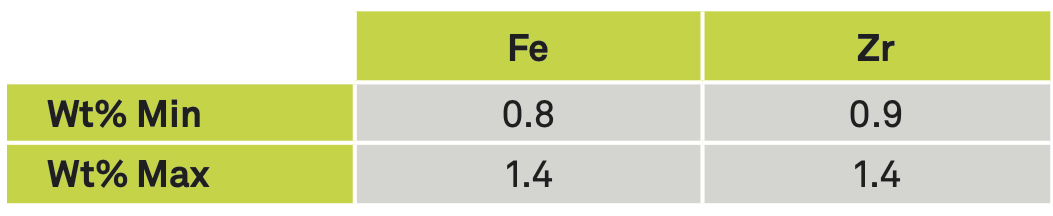

Chemical composition

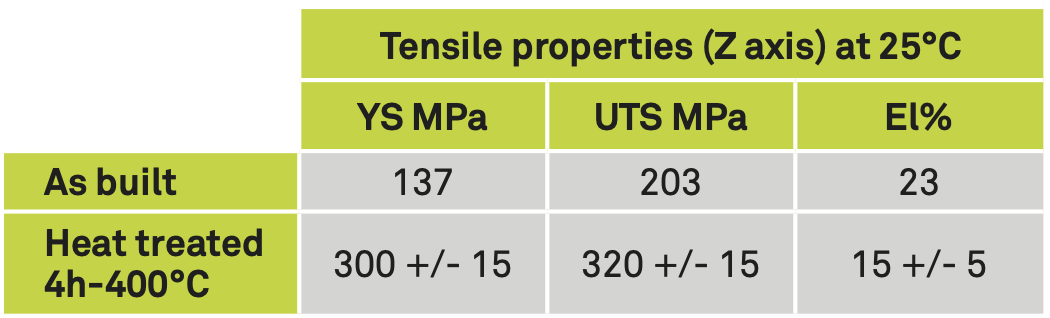

Mechanical properties

The test samples were printed in the EOS M290 the 60µm layers.

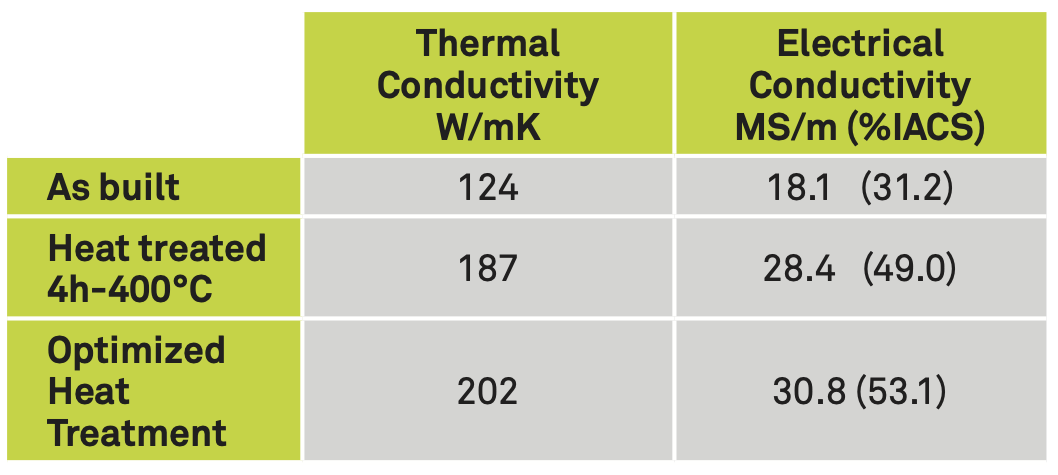

Conductivity

Heat treatment

Standard heat treatment is 4h 400°C (4-7h to adjust mechanical properties). This ageing (precipitation hardening) treatment can be done in air without tight control of ramp & cooling rates. Properties can be tuned with customized heat treatments – information available on request.

Disclaimer

Recommendations are for guidance only and the suitability of the material for any application can only be confirmed upon getting to know the actual service conditions. Continuous development may cause changes in technical data without any prior notice. The current datasheet is only valid for EPlus3D materials.

All test data has been created with a well-maintained machine with well-maintained powder if machine is operated incorrectly or the feed material is not maintained performance of the material may not be seen.

- Alterations to the parameter sets after they have been provided to the customer may also affect the overall performance of the material.

- All tensile testing carried out to (DIN EN ISO 6892-1: 2020-06: A224, DIN 50125:2022-08: B6x30). Orientation Z defined as vertical perpendicular to the build plate. XY orientation defined as Parallel to the plate in the X or Y direction of the top view of the plate.

Metal 3D Printing

Laser powder bed fusion (LPBF) is one of the most popular technologies for fabricating metal 3D parts.

Engineering Solutions

We provide tailored engineering solutions to optimise the design and production process.

Systems and Equipment

Our solution to your needs is beyond a service bureau. We are certified collaborators …

WHY E-3DMETAL?

Nullam suspendisse mauris blandit cum pharetra odio mauris lacus risus. Velit at nam venenatis nunc lorem aliquam.

Safety and security

Egestas faucibus dui sit sagittis mi. Leo tempusinit

Guarantee

Mi ultrices lobortis nullanidun tincidunt non ante in.

Possibility of return

Dignissim et cras consequat nascetur bulla tinci