IN 718

Overview

Inconel 718 (IN718) is a high-strength nickel-based superalloy containing elements like nickel, chromium, and molybdenum, along with additional constituents such as niobium and iron. Recognised for its outstanding high-temperature strength, corrosion resistance, and favourable mechanical properties, it remains robust and durable in extreme environments.

Powder compatibility

DIN 17744 / UNS N07718 / ASTM B637 / ASTM F3055 / 2.4668

GH4169, GH169, NC19FeNb, NA51, Inconel718

Brief introduction

Inconel 718 (IN718) finds widespread use across diverse industries due to its exceptional properties. It is extensively employed in aerospace engineering for components like turbine discs, compressor blades, and rocket engine parts, owing to its high strength and durability at elevated temperatures. Additionally, it’s utilized in the oil and gas sector for wellhead components, downhole equipment, and in the automotive industry for turbocharger rotors and other high-stress engine parts. Its ability to withstand extreme temperatures and harsh environments makes it a reliable choice in numerous critical applications where strength, corrosion resistance, and reliability are paramount.

Powder characteristics

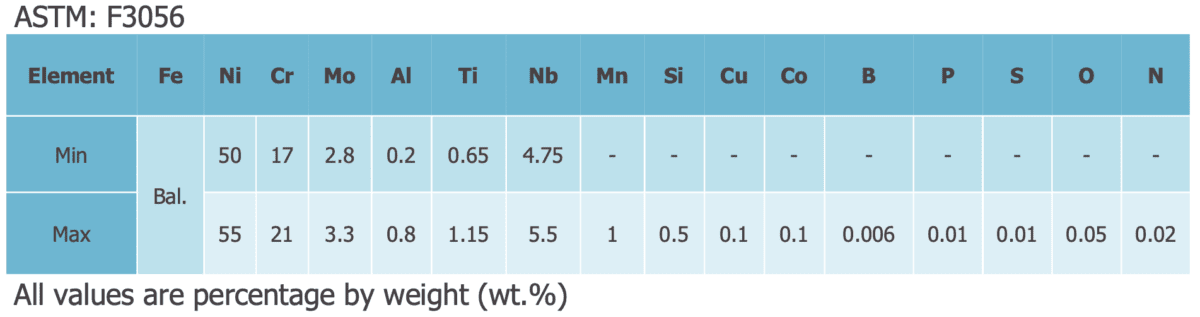

Chemical composition

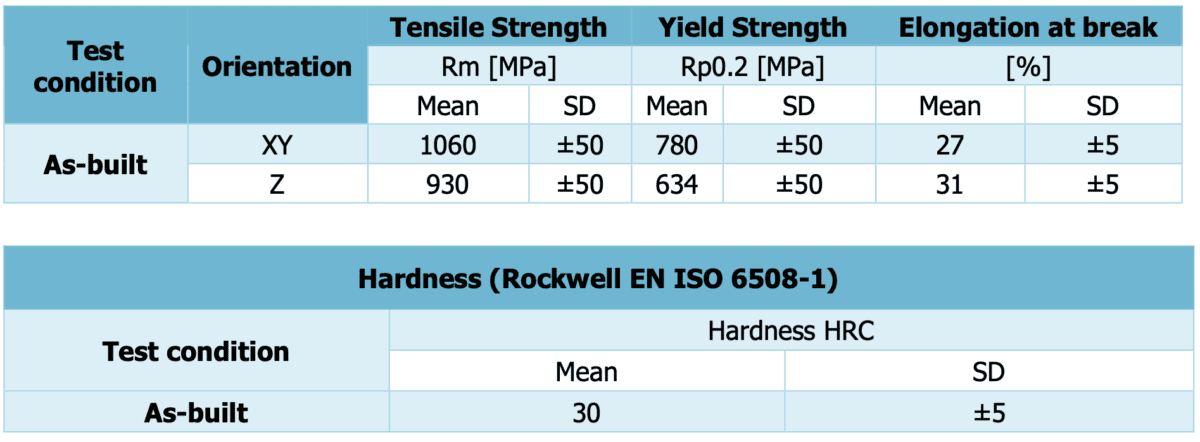

Mechanical properties

The test samples were printed in the EP-M300 & EP-M650 with the 50µm process.

DIN EN ISO 6892-1: 2020-06: A224

DIN 50125:2022-08: B6x30

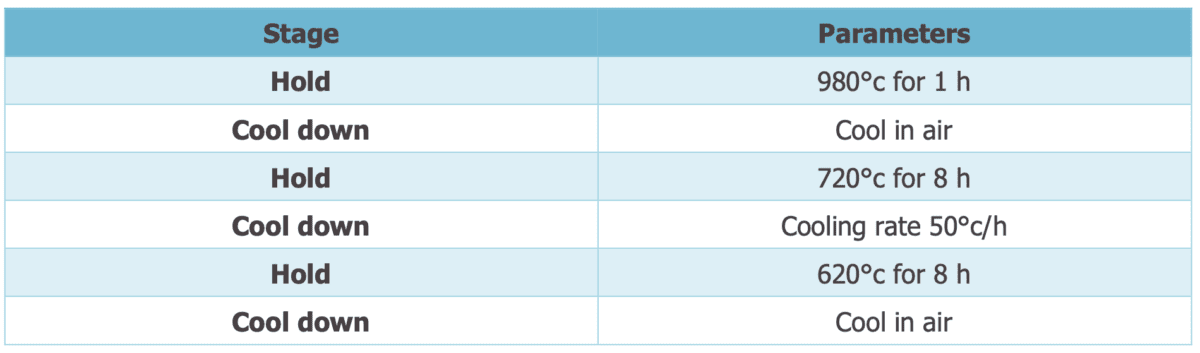

Heat treatment

The heat treatment process for Inconel 718 (IN718) involves a solution treatment, where the alloy is heated to 955°C to 980°C (1750°F to 1800°F) to form a uniform structure, followed by rapid cooling or quenching. Subsequently, aging occurs by reheating the material to around 720°C to 750°C (1325°F to 1380°F) to precipitate fine particles for increased strength, before finally cooling to room temperature. This process optimizes IN718’s mechanical properties, balancing strength, and toughness for various applications.

Recommended Heat treatment:

Disclaimer

Recommendations are for guidance only and the suitability of the material for any application can only be confirmed upon getting to know the actual service conditions. Continuous development may cause changes in technical data without any prior notice. The current datasheet is only valid for EPlus3D materials.

All test data has been created with a well-maintained machine with well-maintained powder if machine is operated incorrectly or the feed material is not maintained performance of the material may not be seen.

- Alterations to the parameter sets after they have been provided to the customer may also affect the overall performance of the material.

- All tensile testing carried out to (DIN EN ISO 6892-1: 2020-06: A224, DIN 50125:2022-08: B6x30). Orientation Z defined as vertical perpendicular to the build plate. XY orientation defined as Parallel to the plate in the X or Y direction of the top view of the plate.

- All Hardness measurements carried out to standard (ISO 6508-1:2016).

Metal 3D Printing

Laser powder bed fusion (LPBF) is one of the most popular technologies for fabricating metal 3D parts.

Engineering Solutions

We provide tailored engineering solutions to optimise the design and production process.

Systems and Equipment

Our solution to your needs is beyond a service bureau. We are certified collaborators …

WHY E-3DMETAL?

Nullam suspendisse mauris blandit cum pharetra odio mauris lacus risus. Velit at nam venenatis nunc lorem aliquam.

Safety and security

Egestas faucibus dui sit sagittis mi. Leo tempusinit

Guarantee

Mi ultrices lobortis nullanidun tincidunt non ante in.

Possibility of return

Dignissim et cras consequat nascetur bulla tinci