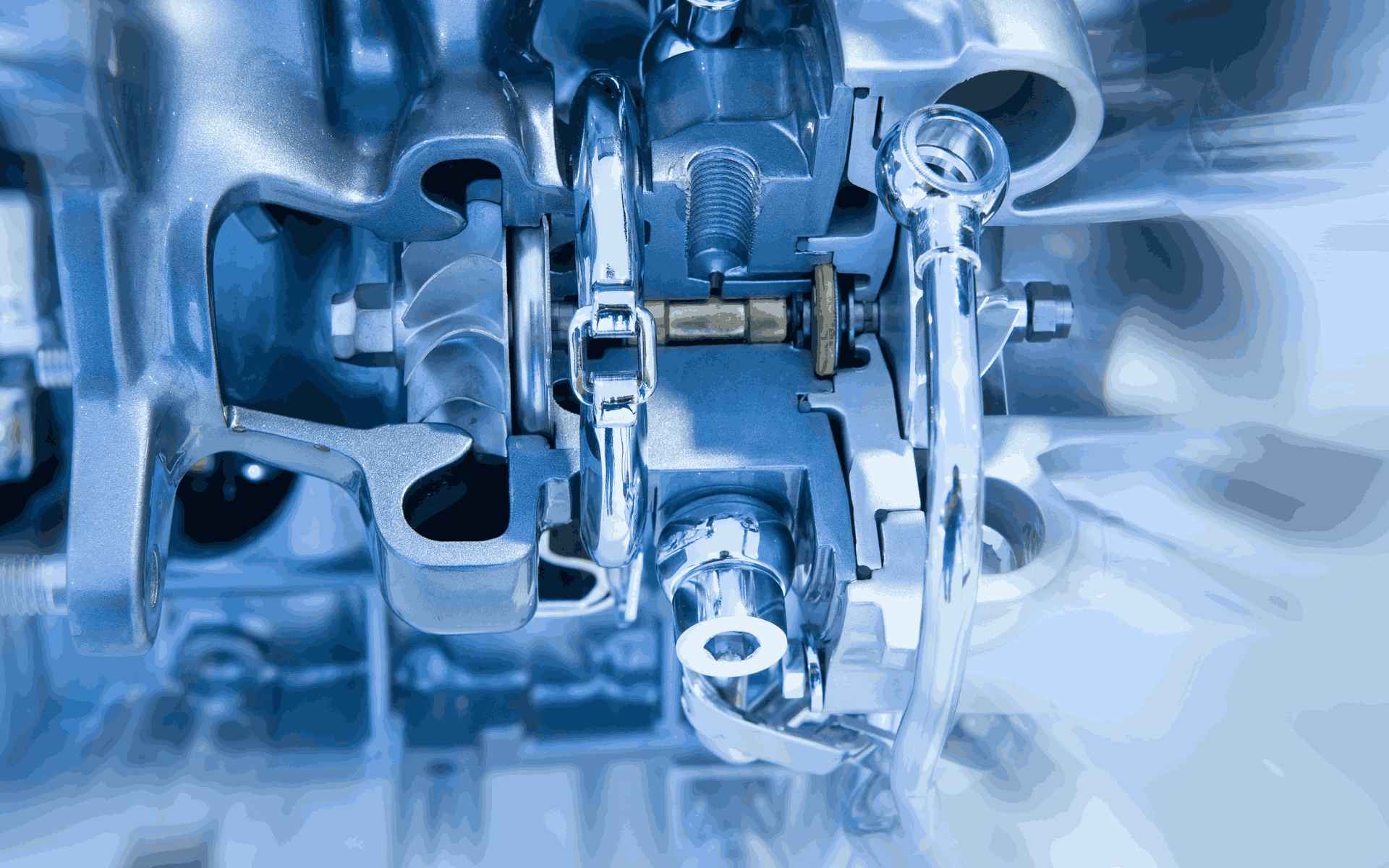

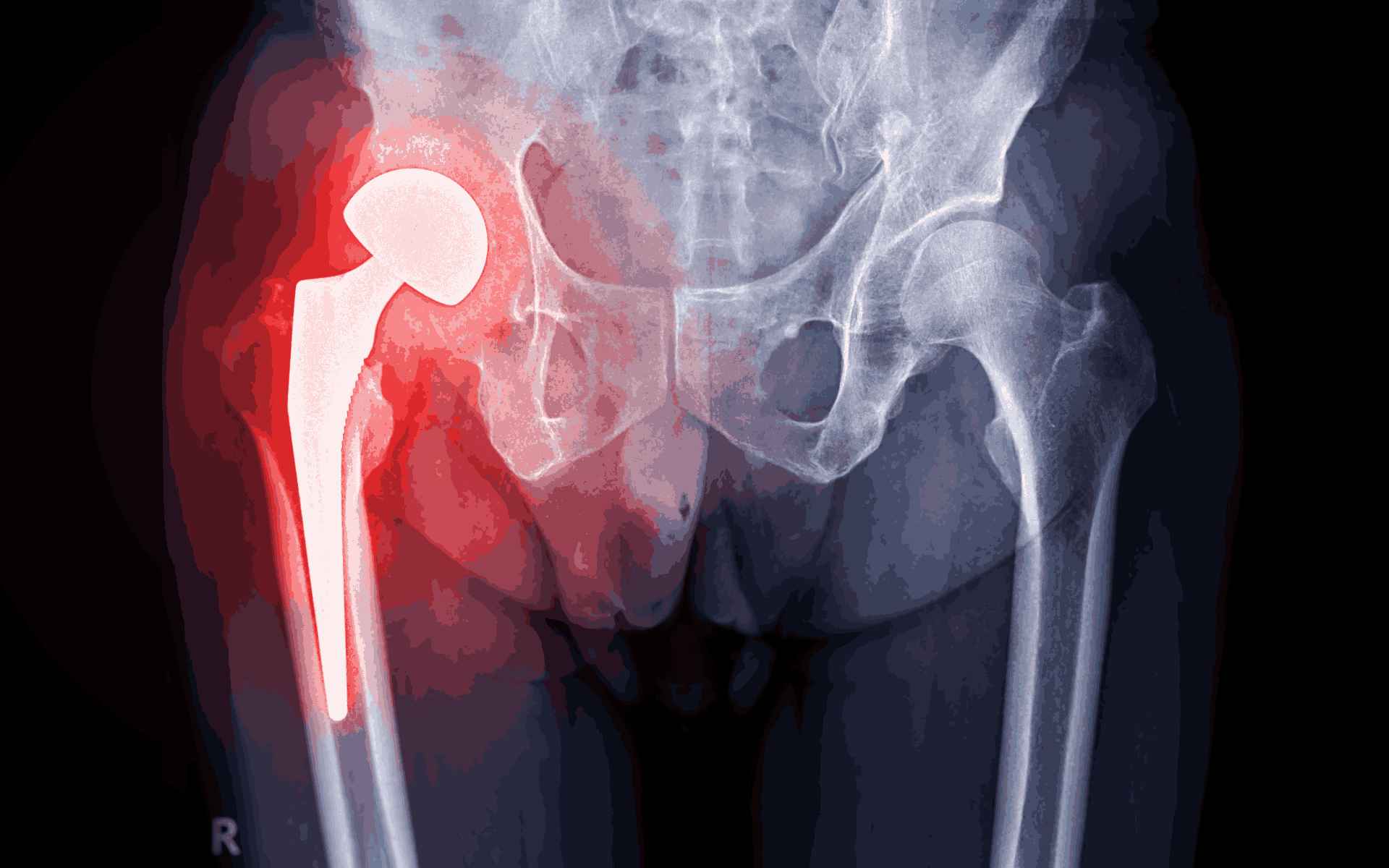

E-Metal3D offers state-of-the-art metal additive manufacturing (AM) services tailored to industries that demand precision, innovation, and efficiency. Our expertise lies in producing high-performance components directly from digital designs using advanced powder bed fusion technologies. This approach eliminates traditional manufacturing constraints, enabling the creation of complex geometries, lightweight structures, and optimised designs that are often impossible with conventional methods. Whether for aerospace, medical implants, mining, oil and gas, or defence applications, our services deliver exceptional part quality, reliability, and repeatability from Stainless Steel, Titanium, Aluminium, or Nickel-based super alloys. We work closely with clients to refine designs for additive manufacturing, ensuring cost-effectiveness, improved functionality, and shorter lead times. Our facilities are equipped to handle both prototype development and production-scale manufacturing, providing flexibility to suit your needs. By leveraging metal 3D printing, clients can reduce material waste, achieve faster product iterations, and gain a competitive edge in their markets.

Our current printing capability covers the following materials:

- Stainless Steel 316L

- Stainless Steel 17-4PH

- Maraging Steel

- Inconel 625

- Inconel 718

- AlSi10Mg

- Ti6Al4V