E-Metal 3D is the official representative of Eplus3D in Australia, providing advanced Additive Manufacturing Systems and Equipment for both metal and polymer applications. With Eplus3D’s state-of-the-art technology and E-Metal 3D’s local expertise, we deliver complete solutions that help Australian industries adopt, integrate, and scale additive manufacturing for efficient production.

Our Systems and Equipment are designed to meet the highest industrial standards, combining precision engineering with innovative 3D printing capabilities. From research and prototyping to full-scale manufacturing, E-Metal 3D ensures that clients receive world-class performance, reliability, and technical support across every stage of their production journey.

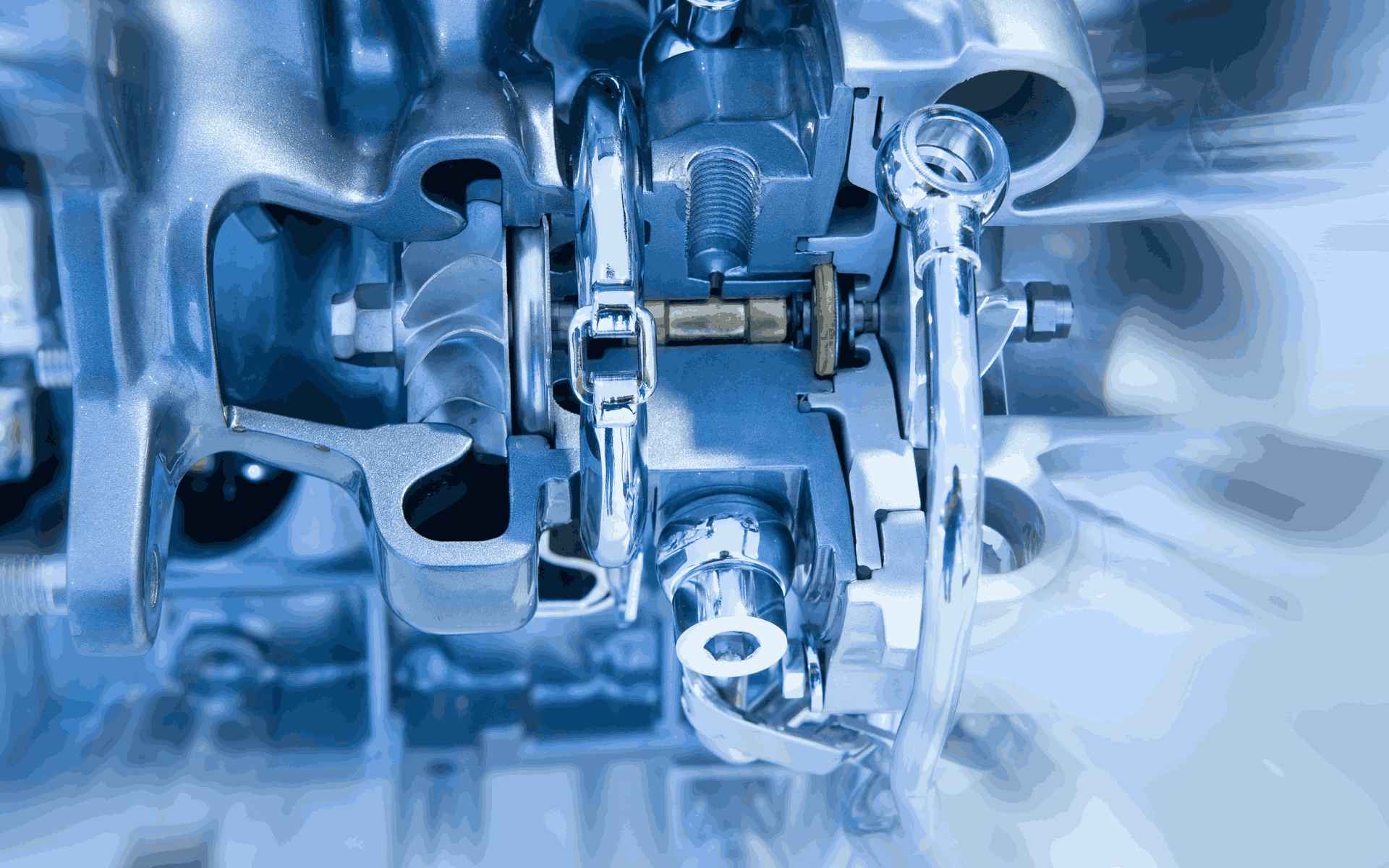

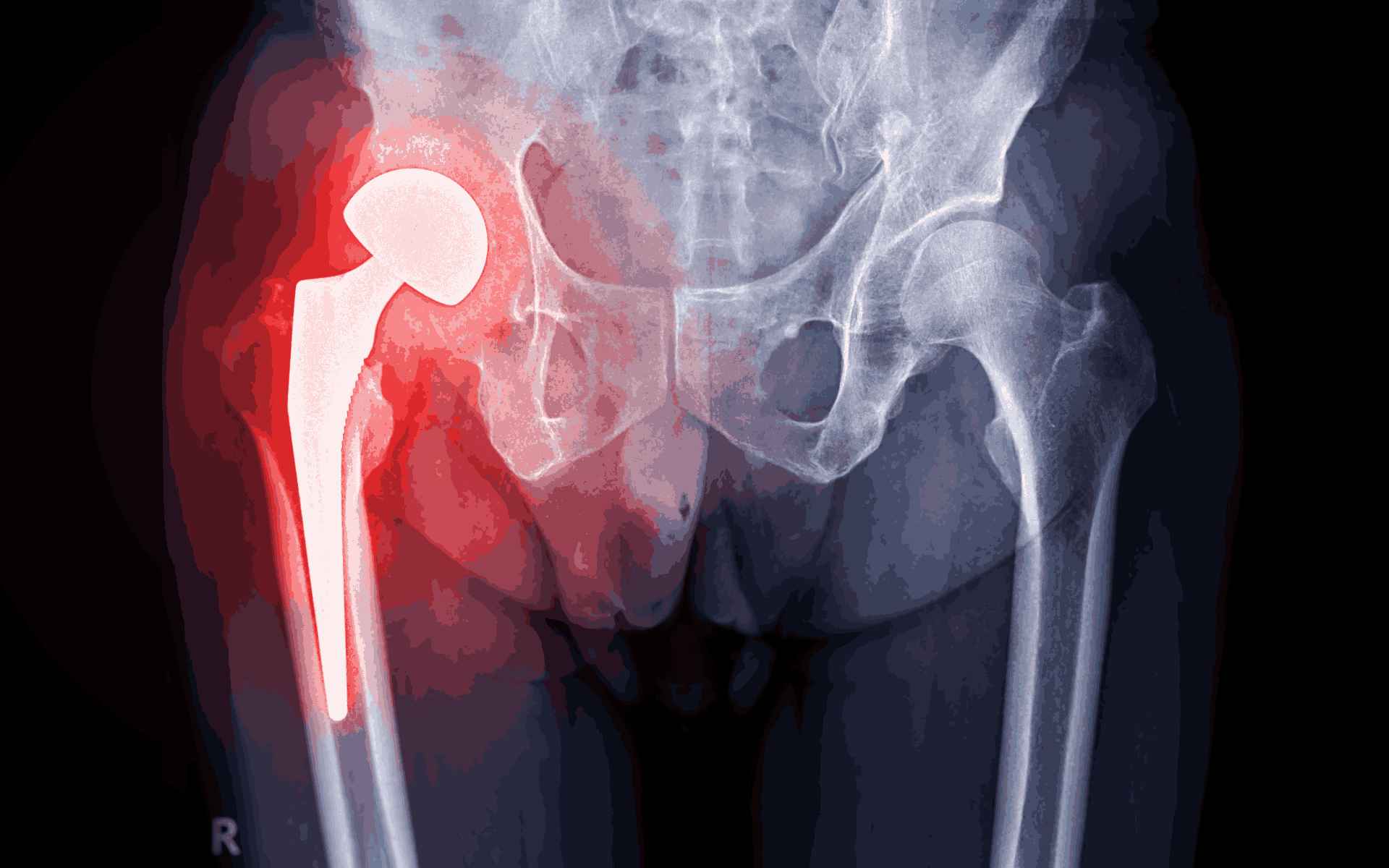

Eplus3D was founded in 2014 and is a global leader in industrial 3D printing technology. The company develops and manufactures high-performance Selective Laser Melting (SLM) and Selective Laser Sintering (SLS) systems for metal and polymer applications. Eplus3D solutions are widely used in aerospace, medical, automotive, tooling, energy, and research industries around the world.

Metal Additive Manufacturing Systems

Eplus3D’s EP-M series of metal 3D printers deliver precision, repeatability, and productivity for demanding industrial applications.

-

EP-M150 – Compact system ideal for dental, jewelry, and research applications.

-

EP-M260 – Versatile mid-size printer for industrial-grade parts and prototyping.

-

EP-M300 Series – Dual and quad-laser configurations for high throughput and consistent part quality.

-

EP-M450 – Large-format system for full-scale production components.

-

EP-M650 – Multi-laser industrial printer with a 650 × 650 mm build area, perfect for aerospace and energy applications.

-

EP-M1550 – Ultra-large-format solution for printing massive structural components.

-

EP-M2050 – The world’s largest powder bed fusion system with 2050x2050x1100 build volume

All Eplus3D metal systems support a wide range of materials, including titanium alloys, aluminum, stainless steel, maraging steel, Inconel, and cobalt-chrome.

Comprehensive Support in Australia

Through E-Metal 3D, Australian customers gain access to:

-

Sales and application support

-

Installation and training

-

Maintenance and spare parts

-

Process development and optimisation

Our team combines decades of experience in advanced manufacturing and mechanical system design to ensure you get the most from your Eplus3D investment.