Metal 3D Printing in the Medical Industry

The medical industry demands the highest level of precision, safety, and customization. Every medical device or implant must be perfectly suited to its purpose — from biocompatibility and mechanical strength to patient-specific geometry. Traditional manufacturing methods, while effective, often face limitations in producing complex, personalized components efficiently.

At E-Metal3D, we help redefine what’s possible in medical manufacturing through advanced metal additive manufacturing (AM). Using Laser Powder Bed Fusion (LPBF) technology, we produce high-performance medical parts that meet the most rigorous standards of quality, precision, and reliability.

Precision Engineering for Healthcare

In modern healthcare, precision saves lives. Metal 3D printing allows for micron-level accuracy and complex internal geometries that are simply impossible to achieve through traditional machining or casting. Whether it’s a surgical instrument, orthopedic implant, or dental component, the LPBF process ensures every detail is perfectly executed.

By combining engineering expertise and advanced design software, our team at E-Metal3D helps medical manufacturers develop components that are not only stronger and lighter but also optimized for biological performance and integration with the human body.

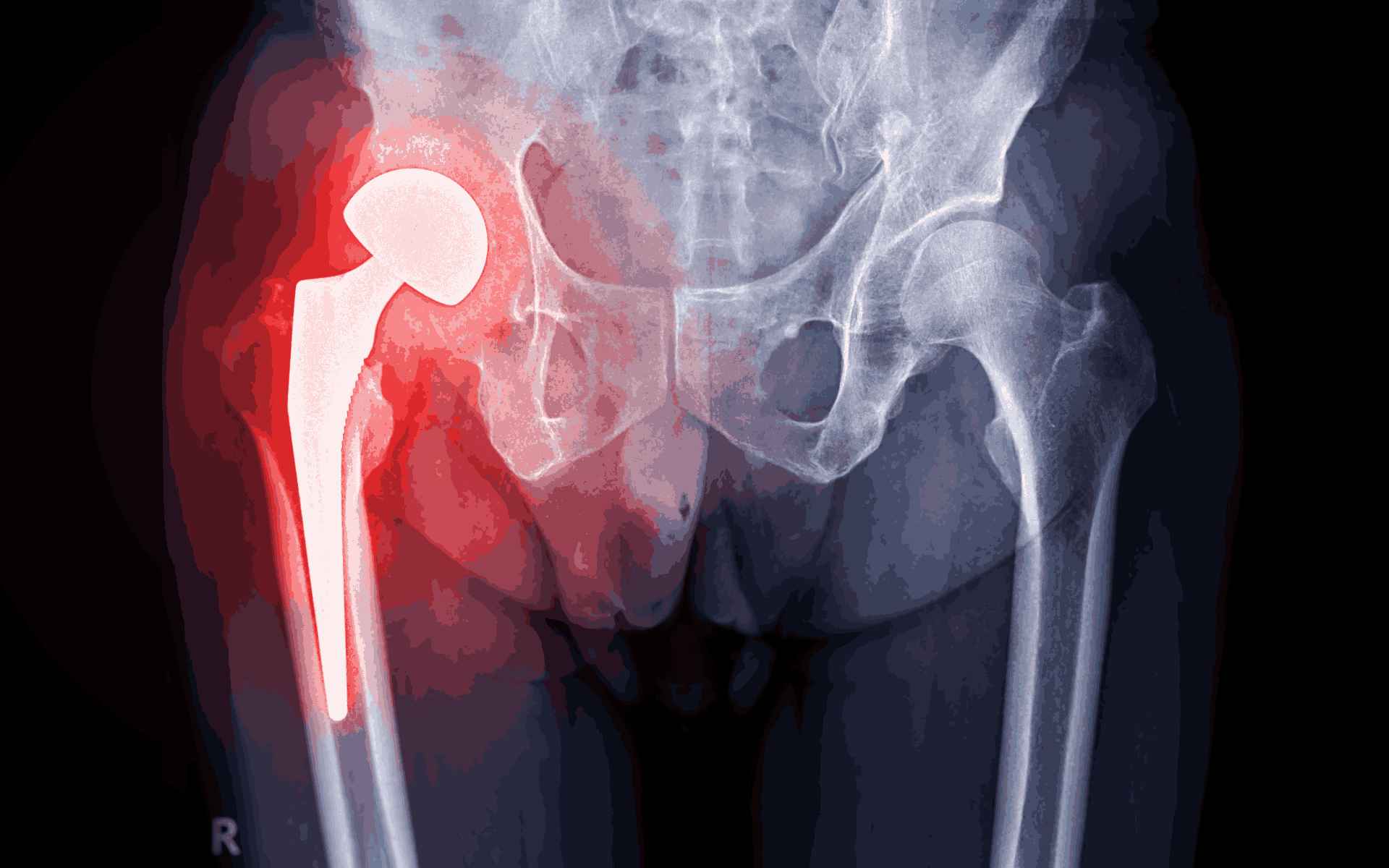

Patient-Specific Implants and Devices

One of the most transformative advantages of metal additive manufacturing in the medical field is mass customization. Every patient is unique — and so should be their implant. With metal 3D printing, medical companies can produce customized implants that match the patient’s anatomy based on CT or MRI scan data.

Examples include cranial plates, spinal cages, hip joints, and dental implants, all created with perfect anatomical fit and surface structures that promote natural bone growth. E-Metal3D ensures that these parts meet biocompatibility and mechanical standards, delivering reliability and comfort to patients.

High-Quality, Certified Materials

E-Metal3D provides a wide range of medical-grade metal powders such as Titanium Ti6Al4V, Stainless Steel 316L, and Cobalt-Chrome (CoCr) — all of which are widely recognized for their biocompatibility, corrosion resistance, and strength-to-weight ratio.

Our materials are certified and traceable, ensuring compliance with international medical standards. Every powder batch undergoes rigorous quality control to maintain purity, consistency, and optimal printing performance.

Rapid Prototyping and Product Development

Innovation in medical technology moves fast — and so do we. With rapid prototyping capabilities, E-Metal3D allows designers and manufacturers to develop, test, and refine new medical products in a fraction of the time compared to traditional methods.

Engineers can print multiple design iterations in a single day, evaluate them for fit, performance, and usability, and then move quickly to production. This accelerated product development cycle helps medical companies stay ahead in a highly competitive market and bring new life-saving technologies to patients faster.

Surface Finishing and Post-Processing Excellence

In the medical industry, surface quality is critical. E-Metal3D provides a variety of surface finishing options, including mirror polishing, glass bead blasting, and electropolishing, to achieve the desired texture and smoothness for implants or instruments.

These finishing processes not only improve the aesthetic and tactile quality of medical components but also enhance biocompatibility, cleanliness, and corrosion resistance — essential factors for surgical and implantable devices.

Regulatory Compliance and Quality Assurance

Our manufacturing process follows strict ISO and ASTM standards to ensure safety and traceability throughout every stage of production. From design validation to final inspection, every part produced at E-Metal3D undergoes meticulous quality control and documentation.

We understand the regulatory challenges in the medical industry and are committed to supporting our clients with documentation, certification, and testing data required for product approval and commercialization.

Sustainability and Efficiency

Additive manufacturing minimizes material waste by using only the required amount of metal powder for each build. Compared to traditional subtractive processes, it’s significantly more resource-efficient and environmentally friendly.

By producing medical components on-demand and locally, E-Metal3D helps reduce logistics costs, lead times, and the carbon footprint associated with global supply chains — making medical manufacturing more sustainable and future-ready.

Partner with E-Metal3D for Medical Innovation

With more than 20 years of engineering expertise and a deep understanding of advanced manufacturing, E-Metal3D is proud to support the medical sector with cutting-edge metal 3D printing solutions.

From concept to production, we provide a one-stop solution for medical device manufacturers — including design assistance, material supply, printing, finishing, and quality certification.

Together, we can bring innovation to life — enabling safer surgeries, faster recoveries, and better patient outcomes through precision metal additive manufacturing.