Metal 3D Printing in the Manufacturing Industry

The manufacturing sector is constantly evolving, driven by demands for faster production, lower costs, higher quality, and greater flexibility. Companies across industries are seeking solutions that allow them to produce complex parts more efficiently, reduce lead times, and adapt to changing market needs.

At E-Metal3D, we bring over 20 years of engineering expertise to empower manufacturers with metal additive manufacturing (AM) — a technology that transforms production processes and opens new possibilities in design and manufacturing efficiency.

Driving Innovation with Additive Manufacturing

Metal 3D printing, particularly Laser Powder Bed Fusion (LPBF), has revolutionized manufacturing by enabling the creation of parts with intricate geometries that were previously impossible or uneconomical to produce.

From custom tools to production components and functional prototypes, additive manufacturing allows manufacturers to design for performance rather than manufacturability.

This flexibility translates into shorter development cycles, reduced costs, and innovative product designs that differentiate companies in competitive markets.

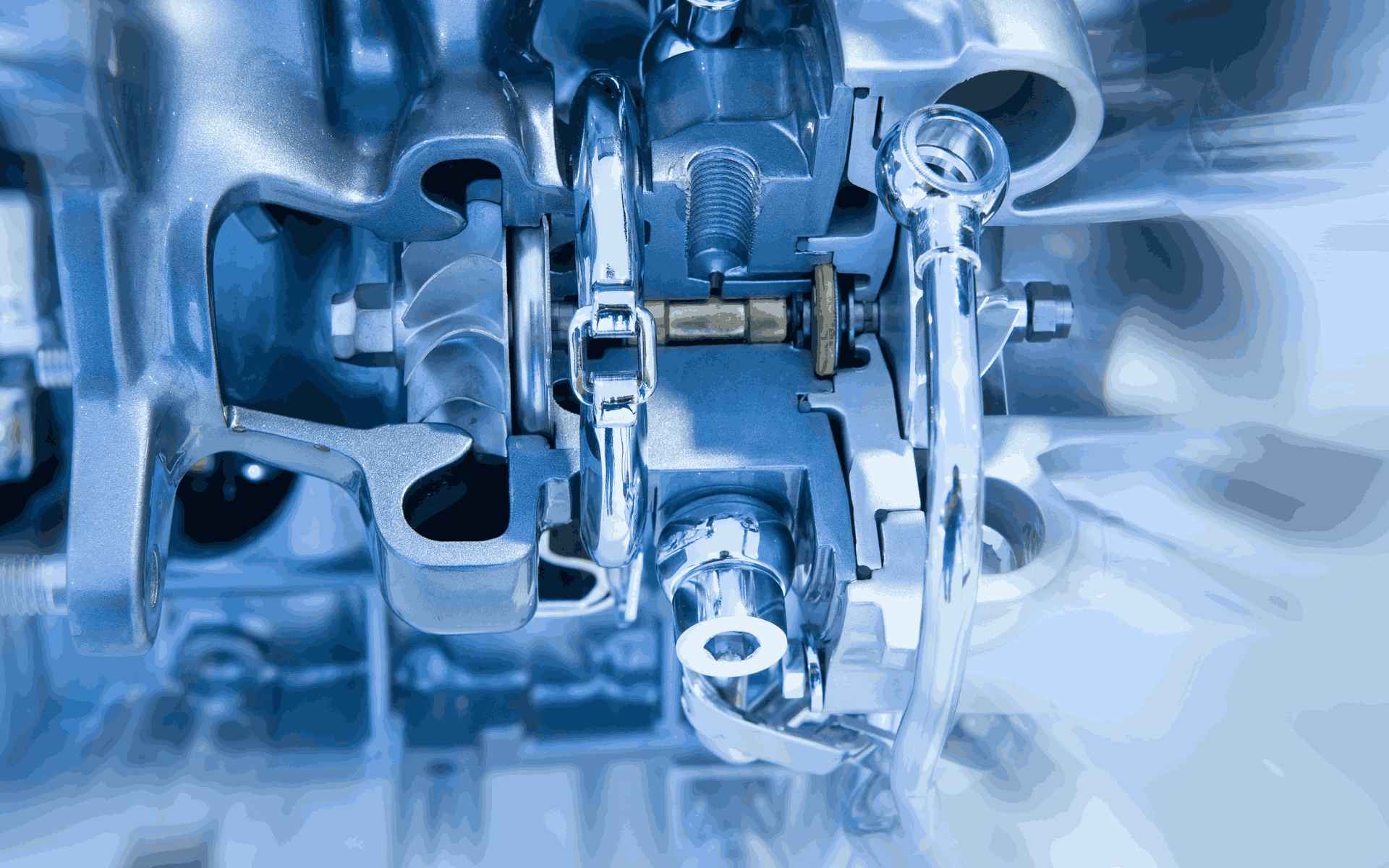

Complex Part Production with Reduced Lead Time

Traditional manufacturing often requires multiple production steps — such as casting, machining, and assembly — which add time and cost to production. Metal additive manufacturing simplifies this process by producing parts layer by layer in a single build.

For example, complex assemblies can be consolidated into a single component, eliminating the need for welding or fasteners. This not only reduces production time but also improves the part’s structural integrity and performance.

E-Metal3D enables manufacturers to produce small to medium batch orders quickly and efficiently, ensuring they can respond faster to customer demands and market changes.

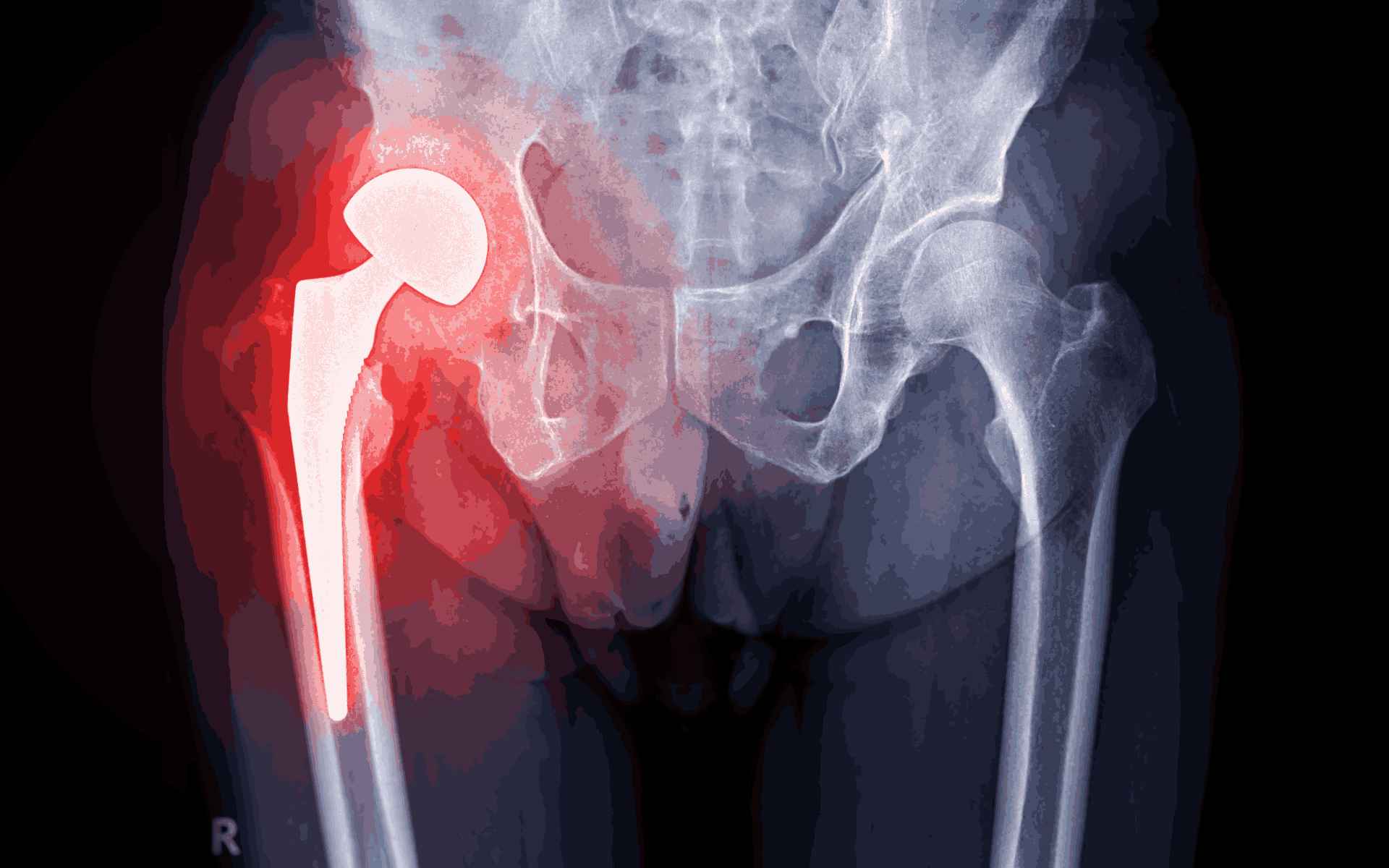

High-Quality, Certified Metal Powders

Material quality is critical for manufacturing excellence. E-Metal3D provides a wide range of certified metal powders, including Titanium alloys, Stainless Steel 316L, Inconel, and Cobalt-Chrome, designed for high-performance applications.

Our powders meet strict quality standards, ensuring consistency and reliability in every print. These materials allow manufacturers to produce parts that deliver superior mechanical properties, corrosion resistance, and durability, even in demanding industrial environments.

Engineering Solutions for Optimized Production

Our engineering solutions team works closely with manufacturers to optimize part designs for additive manufacturing. Using advanced tools such as Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD), we identify areas for improvement, reduce material usage, and enhance part performance.

This engineering-driven approach ensures every component is tailored to its application, balancing performance, cost, and production efficiency.

Prototyping and On-Demand Production

Speed is critical in manufacturing. Metal additive manufacturing offers the ability to rapidly prototype and test new designs, allowing engineers to iterate and refine before committing to full production.

At E-Metal3D, we help manufacturers bring products to market faster by producing prototypes within days instead of weeks. This agility gives manufacturers the competitive advantage of quick innovation and faster delivery to customers.

Additionally, on-demand production allows manufacturers to maintain digital inventories, printing parts as needed. This reduces storage costs and eliminates the risk of part obsolescence.

Cost Efficiency and Sustainability

Additive manufacturing is inherently efficient. Unlike traditional subtractive processes that remove material, AM builds parts layer by layer, using only the necessary amount of metal powder. This reduces material waste by up to 90% and lowers overall production costs.

For manufacturers, this efficiency translates into savings in material costs, reduced lead times, and less reliance on large inventories. It also supports sustainable manufacturing practices by minimizing waste and lowering energy consumption.

Surface Finishing and Post-Processing Expertise

Manufacturing excellence requires not only precision but also quality finishing. E-Metal3D offers a range of post-processing services, including heat treatment, surface polishing, bead blasting, and machining, to deliver parts that meet exact specifications.

Our finishing processes ensure that every component has the right mechanical properties, surface texture, and dimensional accuracy required for high-performance applications.

Future of Manufacturing with Metal AM

Metal additive manufacturing is transforming the manufacturing landscape by enabling greater flexibility, shorter lead times, and innovative product designs. E-Metal3D is at the forefront of this transformation, providing manufacturers with the tools, expertise, and materials they need to stay competitive in a rapidly evolving market.

With our end-to-end metal AM solutions, manufacturers can reimagine product design, streamline production, and deliver high-quality parts with speed and precision — turning challenges into opportunities for growth and innovation.

Partner with E-Metal3D

At E-Metal3D, we understand the unique challenges of modern manufacturing. Our deep engineering expertise and advanced additive manufacturing capabilities allow us to deliver tailored solutions that improve efficiency, reduce costs, and enhance product performance.

We are committed to helping manufacturers harness the full potential of metal 3D printing — turning visionary ideas into reality.