Metal 3D Printing in the Oil and Gas Industry

The oil and gas industry demands high-performance components that can withstand extreme environments—high temperatures, pressure fluctuations, and corrosive conditions. Traditional manufacturing methods often struggle to meet these requirements efficiently. At E-Metal3D, we bring innovation to this field through advanced metal additive manufacturing (AM) technologies such as Laser Powder Bed Fusion (LPBF), enabling the design and production of complex, durable, and lightweight metal parts tailored for the energy sector.

Revolutionizing Component Production

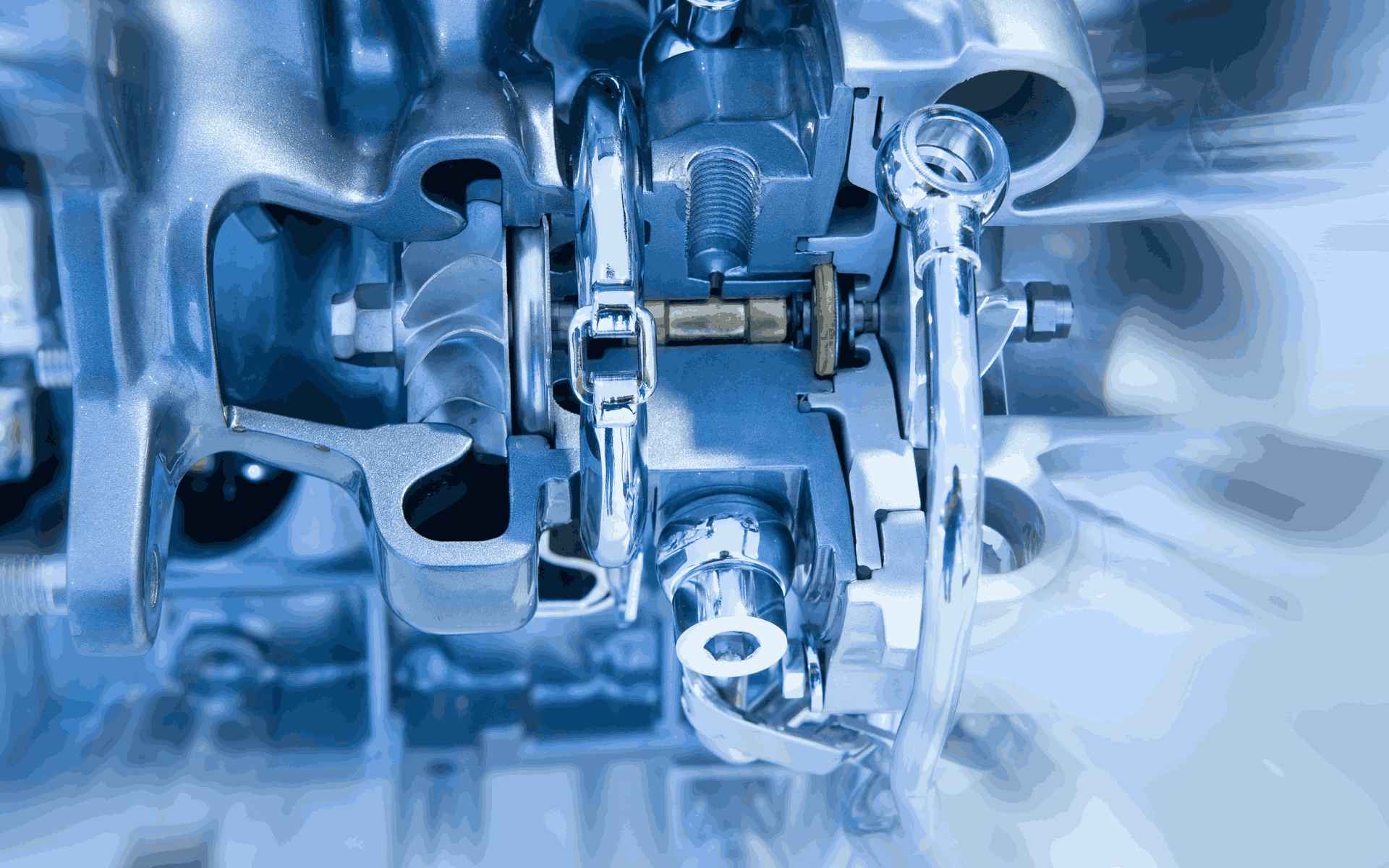

Metal 3D printing transforms how critical oil and gas equipment is designed and manufactured. With LPBF technology, we can produce intricate geometries that were previously impossible or uneconomical using conventional machining or casting. This innovation enables weight reduction, performance optimization, and faster lead times—key advantages for operators seeking efficiency and reliability in their operations.

For instance, components such as pump impellers, valve housings, turbine blades, and flow control devices can be printed as a single consolidated part, reducing the need for multiple welds and joints. This not only enhances mechanical integrity but also minimizes the risk of failure under extreme conditions.

Performance and Material Advantages

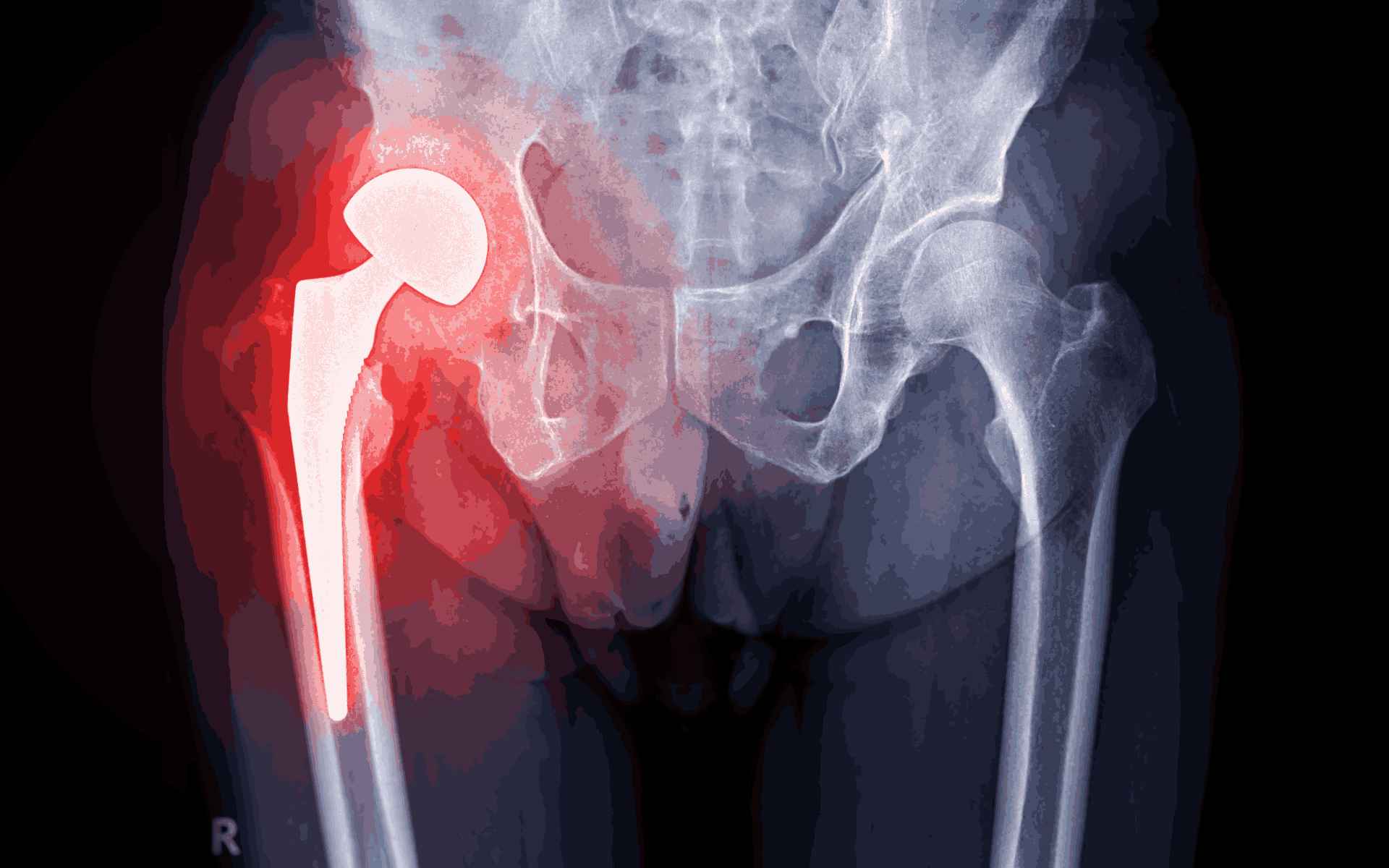

In the oil and gas sector, material selection is crucial. E-Metal3D offers certified metal powders including Stainless Steel 316L, Inconel alloys, Titanium, and Aluminum, all known for their superior corrosion resistance and mechanical strength. These materials are ideal for applications exposed to seawater, chemical agents, and high-temperature environments.

Our in-house powder management and quality assurance systems ensure that every batch of material meets strict industrial standards, providing consistent results across production runs. This guarantees components with reliable performance, long service life, and reduced maintenance costs.

Faster Prototyping and On-Demand Manufacturing

Downtime in the oil and gas industry can cost millions of dollars per day. E-Metal3D’s rapid prototyping and on-demand printing services allow clients to shorten development cycles and respond quickly to operational challenges. Instead of waiting weeks for spare parts, customers can receive fully functional metal components within days, ensuring minimal disruption to critical processes.

Furthermore, digital inventory systems eliminate the need for large-scale warehousing. Once a part is designed and optimized, it can be stored as a digital file and reproduced at any time—anywhere—using our additive manufacturing systems.

Design Optimization and Engineering Support

Beyond production, E-Metal3D provides comprehensive engineering support. Our team collaborates with clients to redesign traditional parts for additive manufacturing, optimizing them for both performance and printability. Using advanced simulation and design software, we identify stress points, reduce weight, and enhance fluid dynamics for components used in pumps, compressors, and flow systems.

Through topology optimization and computational fluid dynamics (CFD) analysis, our engineers ensure that every printed part achieves maximum efficiency and meets all operational requirements.

Sustainability and Cost Efficiency

Metal additive manufacturing is not only faster—it’s also more sustainable. By using only the required amount of powder for each build, waste material is drastically reduced compared to traditional machining. In addition, fewer transport steps, less tooling, and minimal assembly mean lower carbon emissions and overall production costs.

E-Metal3D’s approach aligns with the oil and gas industry’s growing commitment to sustainability and innovation, providing an eco-conscious alternative to traditional metalworking.

Real-World Applications

Our technology has already proven effective in several oil and gas projects. From stainless steel pump casings produced within a week, to custom impellers and connectors designed for offshore operations, E-Metal3D continues to demonstrate the practical and economic value of metal 3D printing.

These successful implementations highlight how additive manufacturing can extend equipment life, improve reliability, and reduce production time, giving energy companies a significant competitive edge.

Partner with E-Metal3D

With more than two decades of engineering and manufacturing expertise, E-Metal3D stands at the forefront of innovation in the oil and gas sector. Whether you need prototype development, custom part production, or design optimization, our team is ready to support you through every stage of your project.

Let us help you rethink what’s possible in energy manufacturing—where precision meets performance, and innovation fuels the future.