At E-Metal3D, we understand that modern manufacturing projects require more than just cutting-edge technology—they demand comprehensive engineering solutions tailored to each client’s unique needs. Our mission is to bridge the gap between concept and reality, providing businesses with the expertise and tools necessary to transform innovative ideas into high-performing, manufacturable products.

Our team of engineers brings decades of experience in mechanical design, advanced manufacturing, and industrial systems. We offer end-to-end engineering solutions across the entire product development cycle—from initial feasibility studies to prototyping, testing, validation, and full-scale production. By integrating traditional engineering knowledge with advanced additive manufacturing capabilities, we ensure that every project achieves maximum efficiency, performance, and cost-effectiveness.

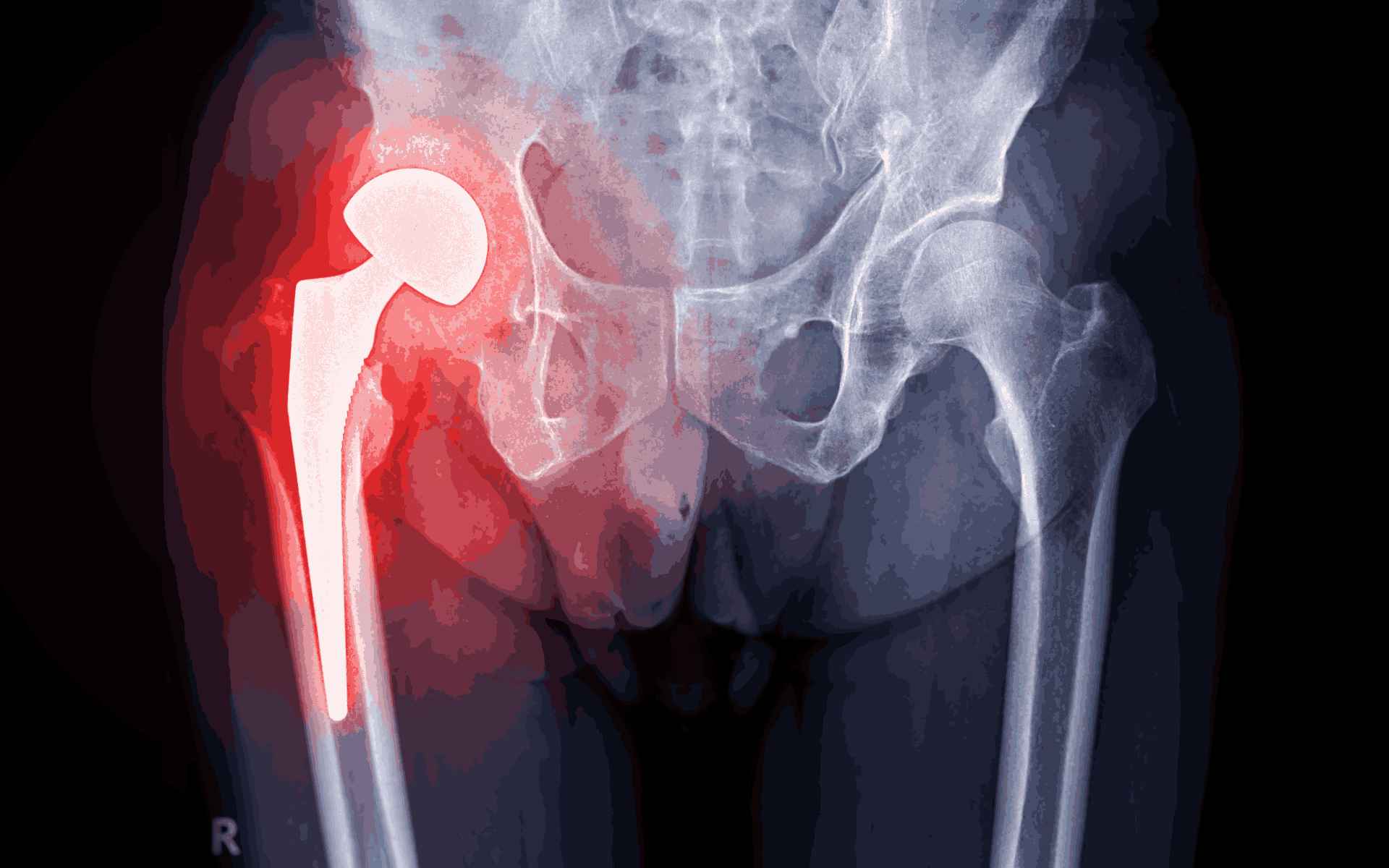

Design for Additive Manufacturing (DfAM) is one of our core competencies. Our engineers specialise in optimising component geometry, reducing weight, and enhancing strength through topology optimisation and innovative material use. We apply lightweighting strategies, lattice structures, and other modern design techniques to help companies create parts that are not only functional but also performance-optimised for their specific industrial environment. Whether you are working on aerospace, medical, automotive, or energy applications, our engineering solutions are designed to meet the rigorous demands of each sector.

We also provide in-depth support for reverse engineering, enabling businesses to recreate or improve existing components with precision and efficiency. By capturing accurate 3D data from physical parts, we can analyse and enhance designs for better durability, performance, and manufacturability. This capability allows companies to innovate on legacy products, reduce production costs, and shorten development cycles.

Complex challenges such as thermal management, fatigue resistance, and material selection are addressed through our advanced engineering expertise. We evaluate each project’s operational conditions, including extreme temperatures, mechanical stress, and environmental factors, to recommend optimal materials and design modifications. By doing so, our engineering solutions ensure that components perform reliably in even the most demanding industrial settings.

Rapid prototyping and testing are integral to our workflow. Using additive manufacturing technologies such as metal 3D printing, we can quickly produce functional prototypes for design validation, iterative testing, and performance evaluation. This approach significantly accelerates time-to-market and reduces risks associated with traditional manufacturing methods. Our engineers work closely with clients to assess prototypes, refine designs, and prepare products for final production, providing continuous support and guidance throughout the process.

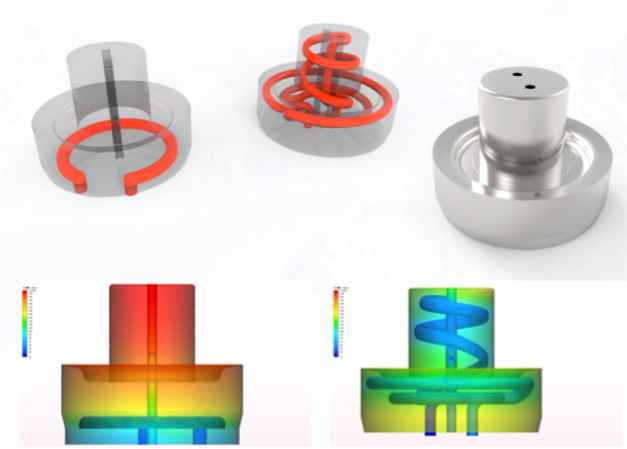

Additionally, we provide engineering consultation for process optimisation, helping manufacturers streamline production workflows, minimise material waste, and improve operational efficiency. Our team collaborates with clients to identify potential bottlenecks, optimise part orientation and support structures, and integrate advanced simulation tools such as Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) into the design process. This comprehensive approach ensures that every solution is robust, efficient, and tailored to the client’s specific needs.

Whether your goal is to enhance an existing product, develop a fully custom component, or explore new applications of additive manufacturing, E-Metal3D’s engineering solutions deliver expertise, creativity, and reliability. Our commitment is to help clients overcome design challenges, reduce production risks, and achieve innovative, high-quality outcomes that meet both technical and business objectives. By combining deep engineering knowledge with state-of-the-art manufacturing technologies, we empower companies to push the boundaries of what’s possible and maintain a competitive edge in their industries.