Metal 3D Printing in the Mining Industry

The mining industry operates in some of the harshest environments on earth — where reliability, durability, and performance of equipment are not just desirable, but absolutely critical. Components are constantly exposed to abrasion, vibration, corrosion, and extreme mechanical stress. Traditional manufacturing methods often struggle to meet these demands efficiently or economically.

At E-Metal3D, we revolutionize the way mining equipment and parts are designed, manufactured, and maintained. Using advanced metal additive manufacturing technologies, such as Laser Powder Bed Fusion (LPBF), we enable mining companies to produce stronger, lighter, and more efficient components with unparalleled precision and speed.

Transforming Mining Equipment Design

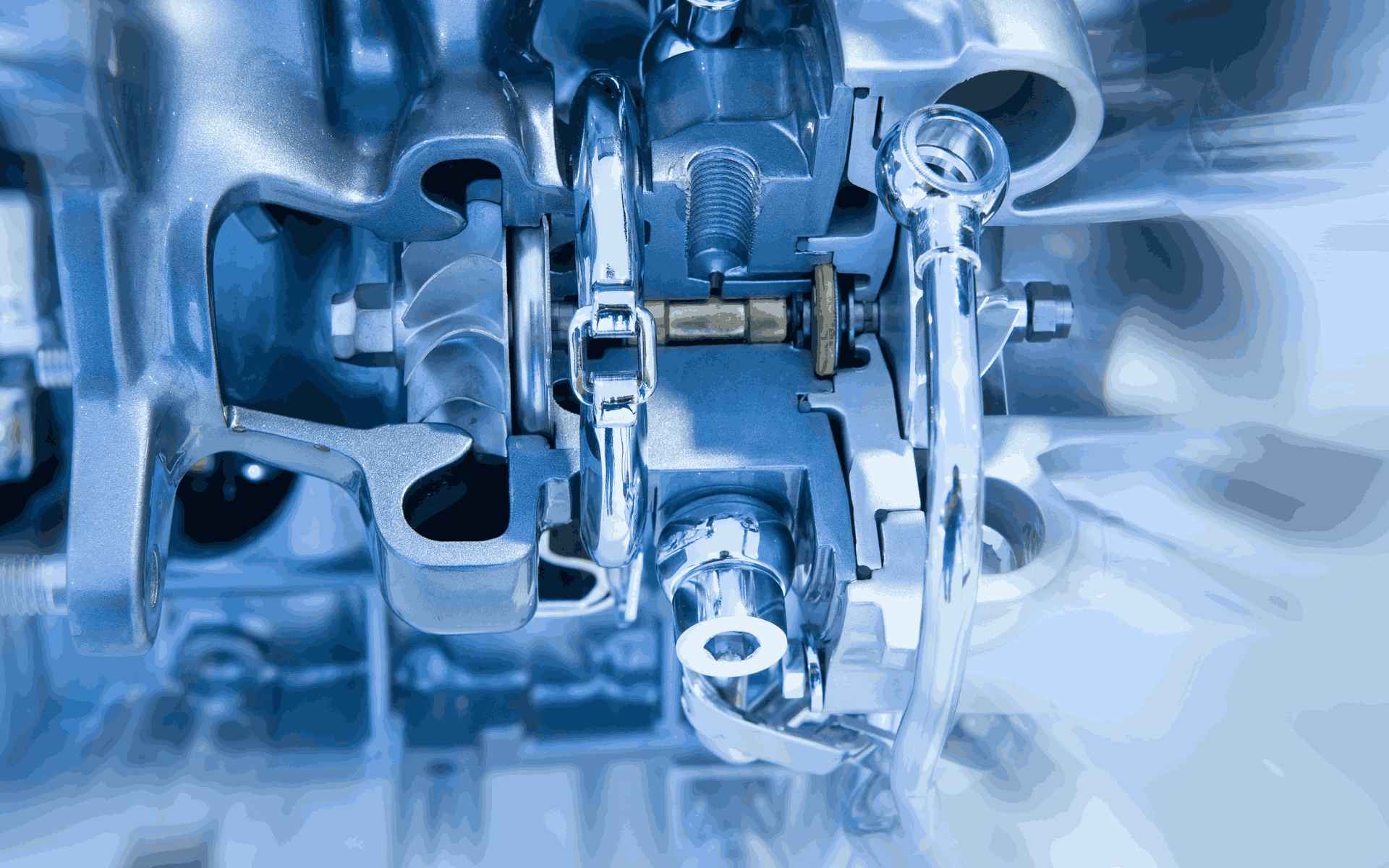

Metal 3D printing allows for geometrical freedom that traditional manufacturing cannot match. Engineers are no longer limited by the constraints of casting or machining. With LPBF, we can create complex internal channels, lattice structures, and optimized geometries that reduce material weight while improving strength and heat dissipation.

For example, cutting tools, rock drill components, impellers, valve housings, and hydraulic connectors can be printed as single-piece components without the need for multiple welds or assemblies. This dramatically reduces the chances of part failure and ensures consistent performance even under severe operating conditions.

Improved Material Performance

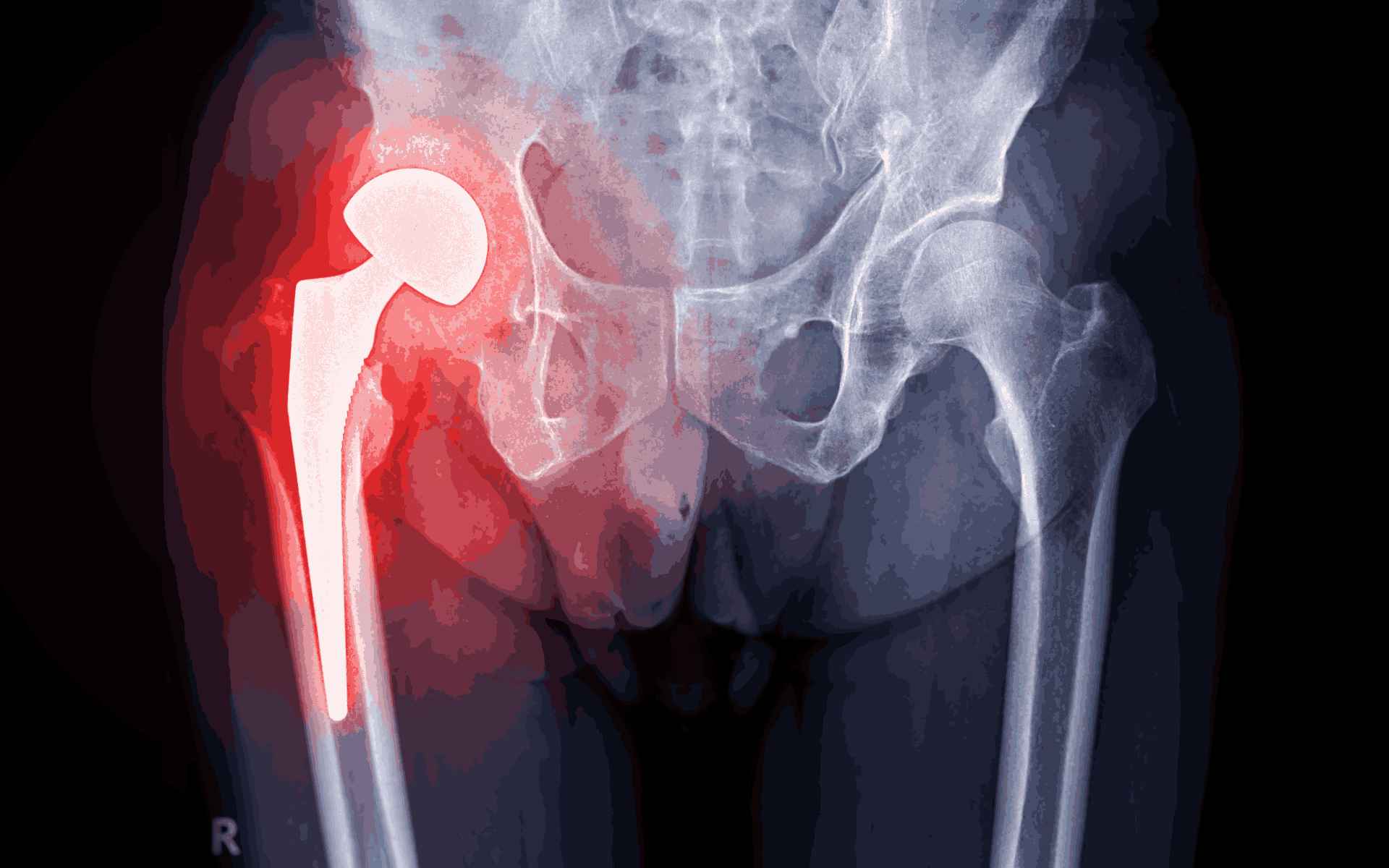

The mining environment requires materials that can endure high stress, temperature fluctuations, and constant exposure to abrasive substances. E-Metal3D provides certified metal powders such as Stainless Steel 316L, Inconel 718, Titanium, and Maraging Steel, all engineered for superior mechanical strength and wear resistance.

These materials ensure that critical components — from pump housings and nozzles to bearing supports and gear parts — maintain their structural integrity and longevity even after prolonged operation. Moreover, our in-house quality control system guarantees consistent powder quality and part reliability, meeting international industrial standards.

Rapid Prototyping and On-Demand Production

Downtime in the mining sector is extremely costly. Equipment failure can halt entire operations for days or weeks. With E-Metal3D’s rapid prototyping and on-demand production, spare parts and replacement components can be designed, printed, and delivered within days — drastically reducing downtime and improving productivity.

Instead of waiting for overseas shipments or tooling lead times, mining operators can rely on local, digital manufacturing solutions. Once a design is validated, it can be stored as a digital blueprint and reproduced instantly whenever needed, minimizing dependency on traditional supply chains.

Design Optimization and Engineering Expertise

Our engineering solutions team collaborates closely with mining companies to redesign and optimize existing parts for additive manufacturing. Through advanced simulation and analysis tools — such as Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) — we identify stress points, reduce material waste, and enhance component efficiency.

This engineering-driven approach ensures that every printed part performs at its highest potential while also being more cost-effective and environmentally sustainable.

Sustainability Through Additive Manufacturing

Mining companies today are under growing pressure to adopt sustainable and resource-efficient technologies. Metal 3D printing plays a significant role in this transition. The LPBF process uses only the required amount of metal powder for each print, significantly reducing waste compared to machining, which can discard up to 80% of raw material.

Additionally, the ability to produce parts locally minimizes logistics and carbon emissions. E-Metal3D supports this sustainable vision by helping clients reduce environmental impact without compromising performance or safety.

Real-World Applications

Our technology has already been successfully implemented in multiple mining projects. From titanium alloy cutting tools produced in large batches to custom pump components and heat exchangers printed for extreme durability, E-Metal3D has demonstrated the value of metal additive manufacturing in real-world mining operations.

In one case, stainless steel pump casings were printed within just a week, allowing a mining plant to resume operations without extended downtime. These case studies highlight how 3D printing is redefining what’s possible in equipment repair, maintenance, and design.

Partner with E-Metal3D

With more than 20 years of experience in engineering and advanced manufacturing, E-Metal3D is your trusted partner for innovation in the mining industry. We combine cutting-edge AM technology, engineering expertise, and reliable material solutions to help you improve operational efficiency, reduce costs, and extend the lifespan of your equipment.

Let us help you unlock the future of mining — where performance meets precision, and innovation drives sustainability.