The mining industry operates in some of the most demanding environments on the planet. Extreme abrasion, high mechanical loads, corrosion, and continuous operation place enormous stress on mining equipment and components. Equipment downtime is exceptionally costly, while supply chain delays—especially for remote mining sites—can halt operations for weeks or even months.

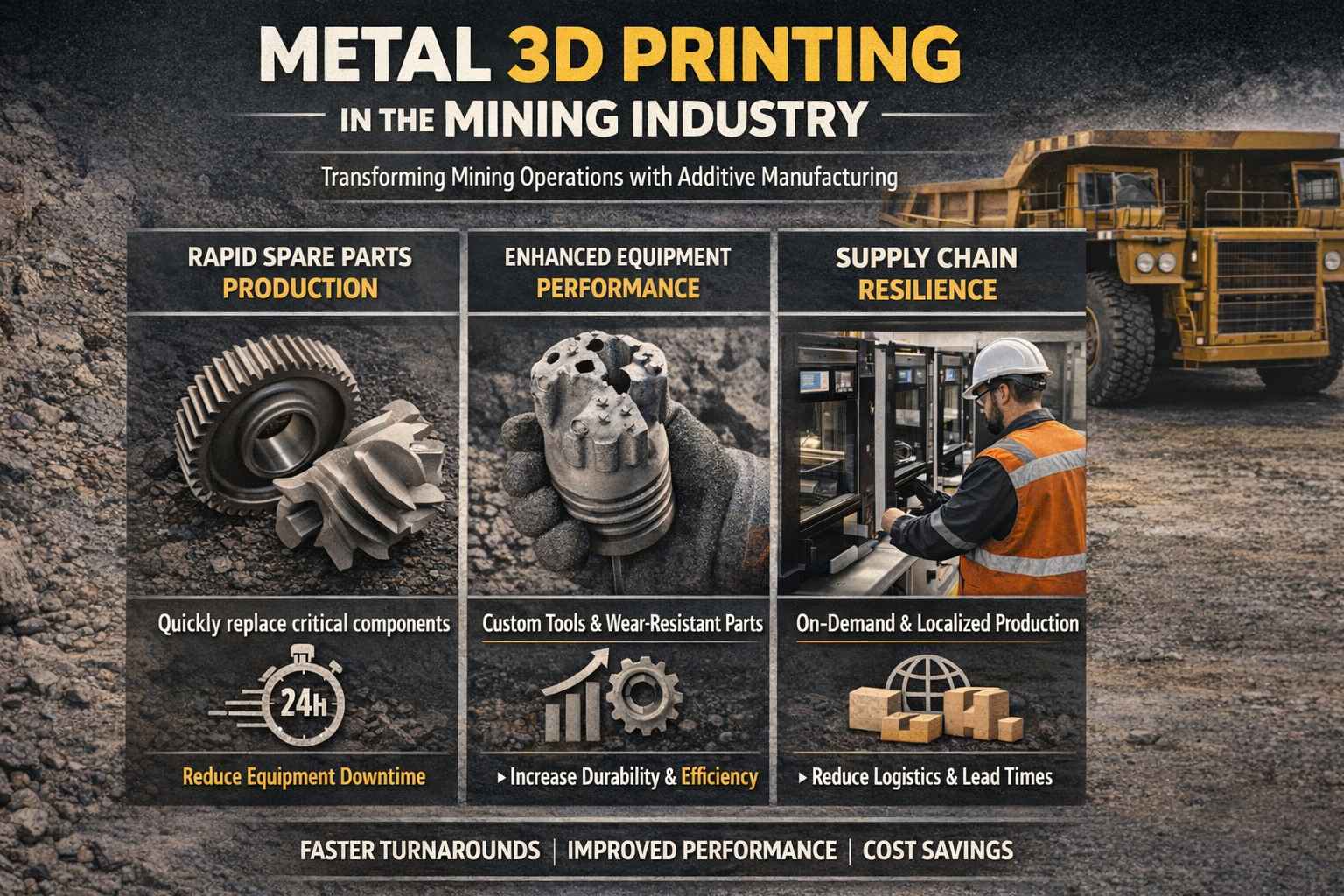

In response to these challenges, Metal Additive Manufacturing (Metal 3D Printing) has emerged as a practical and transformative solution. Once viewed as an experimental or prototyping technology, metal 3D printing is now being deployed in real mining operations worldwide to manufacture spare parts, optimize component design, repair high-value equipment, and increase operational resilience.

This article explores real-world applications of metal 3D printing in the mining industry, highlighting how mining companies are leveraging additive manufacturing to reduce costs, improve reliability, and gain strategic advantages.

Why Metal 3D Printing Is Well-Suited for Mining

Mining presents a unique combination of challenges that align perfectly with the strengths of metal additive manufacturing:

-

Harsh operating conditions (abrasion, impact, heat, corrosion)

-

Low-volume, highly specialized components

-

Long lead times for replacement parts

-

Remote locations with limited logistics access

-

High cost of equipment downtime

Metal 3D printing enables localized, on-demand, and design-optimized production, making it an ideal manufacturing method for modern mining operations.

1. On-Demand Production of Critical Spare Parts

One of the most impactful real-world applications of metal 3D printing in mining is on-demand spare part manufacturing.

Practical examples include:

-

Crusher wear components and housings

-

Gearboxes, shafts, and brackets

-

Pump impellers and valve components

-

Legacy parts no longer supported by OEMs

Using technologies such as Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS), mining companies have reduced spare-part lead times from several months to just a few days. This capability dramatically lowers unplanned downtime and eliminates dependency on global supply chains.

2. Design Optimization for Improved Durability and Performance

Metal 3D printing enables engineers to move beyond traditional design constraints and optimize mining components for real operating conditions.

Real-world design improvements include:

-

Internal lattice structures to reduce weight while maintaining strength

-

Optimized material distribution to resist impact and fatigue

-

Integrated cooling or stress-relief channels

-

Enhanced wear surfaces without increasing overall mass

Several large mining operations have reported significant lifespan extensions for additively manufactured components compared to conventionally produced parts.

3. Repair and Remanufacturing of High-Value Components

Rather than replacing expensive components, mining companies increasingly use metal additive manufacturing for repair and remanufacturing.

Common applications:

-

Restoring worn drilling tools

-

Rebuilding damaged pump housings

-

Repairing high-stress contact surfaces

-

Extending the life of oversized components

Processes such as Directed Energy Deposition (DED) allow material to be added precisely where needed, reducing waste and costs while maintaining structural integrity.

4. Custom Tools, Jigs, and Fixtures for Mining Operations

Mining operations often require specialized tools that are unavailable commercially or are prohibitively expensive to machine.

Metal 3D printing enables rapid production of:

-

Assembly and alignment fixtures

-

Heavy-duty maintenance tools

-

Custom lifting and handling devices

-

Safety-related components designed for specific site conditions

These tools can be designed, produced, and deployed quickly, improving maintenance efficiency and worker safety.

5. Supply Chain Resilience and Digital Inventory

One of the most strategic advantages of metal 3D printing is the transition from physical inventories to digital inventories.

By storing qualified CAD files instead of physical spare parts, mining companies can:

-

Reduce warehouse costs

-

Minimize capital tied up in stock

-

Eliminate obsolete inventory

-

Manufacture parts closer to the point of use

This approach has proven particularly valuable for remote and offshore mining sites, where logistics delays can severely impact production.

6. High-Performance Materials for Mining Applications

Metal additive manufacturing supports a wide range of advanced materials suitable for mining environments, including:

-

Wear-resistant tool steels

-

Maraging steels

-

Stainless steels with enhanced corrosion resistance

-

Nickel-based superalloys

-

Custom alloy compositions optimized for abrasion and impact

These materials enable the production of components that outperform traditional cast or machined equivalents under extreme operating conditions.

7. Real-World Industry Case Examples

Rio Tinto

Implemented metal 3D printing for spare part production, reducing lead times and improving operational uptime across multiple mining sites.

BHP

Adopted additive manufacturing to support maintenance operations and minimize equipment downtime in remote locations.

Anglo American

Established additive manufacturing centers to enhance supply chain resilience and accelerate equipment maintenance.

These examples demonstrate that metal 3D printing is already delivering measurable value in real mining environments.

Proven Benefits of Metal 3D Printing in Mining

Mining companies using metal additive manufacturing report:

-

Reduced equipment downtime

-

Lower spare-part costs

-

Faster response to maintenance issues

-

Improved component performance

-

Increased operational flexibility

Implementation Challenges and Considerations

Despite its advantages, successful adoption requires:

-

Material qualification and testing

-

Process validation and quality control

-

Skilled engineering and AM expertise

-

Compliance with industry standards

Mining companies that invest in proper implementation frameworks achieve the highest returns from metal AM.

The Future of Metal 3D Printing in Mining

As mining operations continue to digitize, metal 3D printing will play an increasingly central role—especially when combined with:

-

Predictive maintenance

-

Smart mining systems

-

AI-driven design optimization

-

On-site additive manufacturing hubs

The future points toward distributed, resilient, and highly efficient mining operations powered by additive manufacturing.

Conclusion

Real-world applications of metal 3D printing in the mining industry clearly demonstrate that this technology is no longer experimental. It is a proven, industrial-grade solution that enables mining companies to reduce costs, increase uptime, and gain long-term strategic advantages.

Mining organizations that adopt metal additive manufacturing today are positioning themselves for greater resilience, sustainability, and competitiveness in the years ahead.