The mining industry faces increasing pressure to improve sustainability while maintaining operational efficiency and profitability. Rising energy costs, stricter environmental regulations, supply chain disruptions, and growing expectations for responsible resource management are forcing mining companies to rethink traditional manufacturing and maintenance practices.

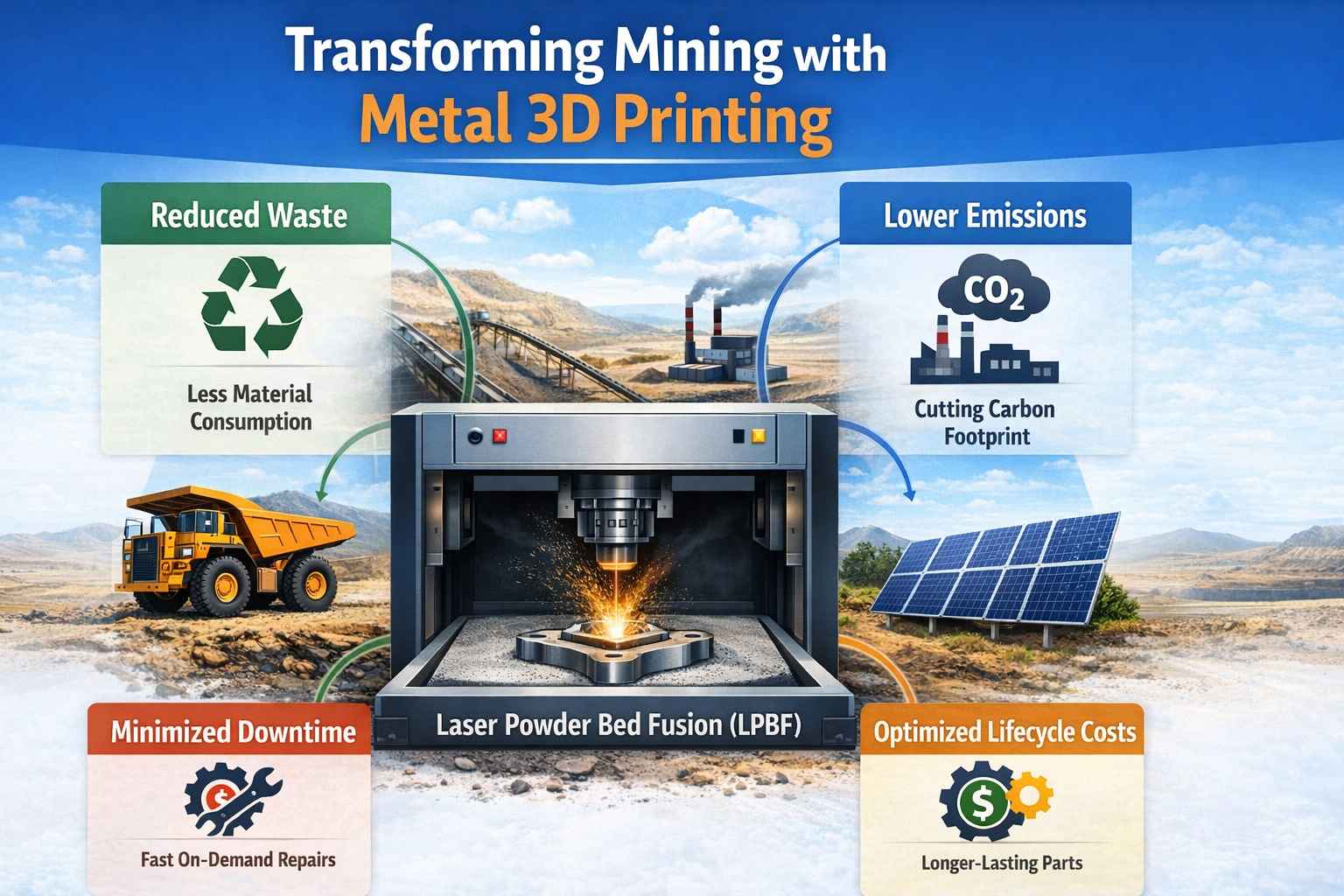

Metal additive manufacturing (AM), particularly Laser Powder Bed Fusion (LPBF), has emerged as a powerful enabler of both sustainability and cost reduction in mining operations. By enabling localized, efficient, and digitally driven production, metal 3D printing helps mining companies reduce waste, lower emissions, minimize downtime, and optimize lifecycle costs of critical components.

This article explores how metal additive manufacturing is transforming mining operations by aligning economic performance with sustainable manufacturing principles.

Sustainability Challenges in the Mining Industry

Mining is inherently resource-intensive. Equipment operates continuously in harsh environments, leading to high wear rates, frequent part replacement, and significant material consumption. Traditional manufacturing approaches exacerbate these challenges through:

-

High material waste from subtractive machining

-

Long-distance transportation of spare parts

-

Excessive inventory and warehousing

-

Energy-intensive production processes

-

Premature equipment replacement instead of repair

As environmental, social, and governance (ESG) requirements become more stringent, mining companies must adopt smarter manufacturing strategies that reduce environmental impact without compromising performance.

Metal Additive Manufacturing as a Sustainable Solution

Metal additive manufacturing builds parts layer by layer using only the material required for the final geometry. This fundamental difference from traditional subtractive manufacturing results in significantly higher material efficiency and lower waste.

Key sustainability advantages include:

-

Up to 90% reduction in raw material waste

-

Lower energy consumption per part for complex geometries

-

Reduced need for tooling and molds

-

Minimal scrap generation

-

Extended component lifecycle through design optimization

These benefits make metal AM an ideal technology for sustainable mining operations.

Material Efficiency and Waste Reduction

Traditional machining often removes large volumes of material to achieve final part geometry, discarding up to 70–80% of the original billet. In contrast, LPBF uses metal powder selectively and efficiently.

Unused powder can be recovered, sieved, and reused, dramatically reducing waste. This is particularly valuable when working with high-cost alloys such as Inconel, titanium, and maraging steels commonly used in mining applications.

By minimizing waste, mining companies not only reduce material costs but also lower their environmental footprint.

Cost Reduction Through Part Consolidation

Metal AM enables complex geometries that allow multiple components to be consolidated into a single printed part. This eliminates:

-

Welding and fasteners

-

Assembly labor

-

Inspection and failure points

-

Inventory complexity

For mining equipment, part consolidation improves reliability while significantly reducing manufacturing and maintenance costs. Fewer components mean fewer failures and less downtime—both critical cost drivers in mining operations.

On-Demand Manufacturing and Digital Inventory

One of the most impactful cost-saving benefits of metal additive manufacturing is on-demand production. Instead of maintaining large inventories of spare parts, mining companies can store digital CAD files and manufacture parts only when needed.

This approach reduces:

-

Inventory holding costs

-

Obsolete stock

-

Emergency shipping expenses

-

Dependency on overseas suppliers

Digital inventory combined with local production enables faster response to equipment failures while supporting more sustainable logistics.

Reduced Downtime and Operational Losses

Unplanned downtime is one of the largest hidden costs in mining. Metal AM allows rapid replacement of worn or damaged parts, often within days.

By reducing lead times for spare parts production, mining companies can:

-

Resume operations faster

-

Avoid prolonged shutdowns

-

Maintain production schedules

-

Improve overall equipment effectiveness (OEE)

The economic impact of downtime reduction alone often justifies the adoption of metal additive manufacturing.

Design Optimization for Performance and Longevity

Metal AM enables engineers to redesign mining components for improved performance rather than manufacturability. Using simulation tools such as Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD), components can be optimized for:

-

Stress distribution

-

Wear resistance

-

Weight reduction

-

Thermal management

Optimized designs extend part lifespan, reduce replacement frequency, and improve energy efficiency—directly contributing to sustainability and cost savings.

Repair, Remanufacturing, and Lifecycle Extension

Instead of discarding worn components, metal additive manufacturing enables repair and remanufacturing strategies. Damaged areas can be rebuilt or reinforced, restoring functionality and extending service life.

This approach:

-

Reduces raw material consumption

-

Lowers replacement costs

-

Minimizes waste generation

-

Supports circular economy principles

For mining companies, remanufacturing critical parts represents a sustainable alternative to full replacement.

Lower Carbon Footprint Through Local Production

Global supply chains contribute significantly to carbon emissions due to transportation and logistics. By producing spare parts locally using metal AM, mining operators can dramatically reduce their carbon footprint.

Local manufacturing also improves supply chain resilience, ensuring continuity even during global disruptions.

Certified Materials for Sustainable Performance

High-performance metal powders such as Stainless Steel 316L, Inconel 718, Titanium alloys, and Maraging Steel are specifically engineered for durability and long service life.

Certified powders ensure:

-

Consistent mechanical properties

-

Reduced failure rates

-

Predictable performance

-

Compliance with international standards

Longer-lasting components reduce the frequency of replacements, further supporting sustainability goals.

Alignment with ESG and Regulatory Requirements

Sustainability is no longer optional. Investors, regulators, and stakeholders increasingly expect mining companies to demonstrate responsible resource management.

Metal additive manufacturing supports ESG objectives by:

-

Reducing waste and emissions

-

Improving energy efficiency

-

Enabling responsible sourcing

-

Supporting safer, more reliable operations

Adopting AM positions mining companies as forward-thinking and environmentally responsible.

Real-World Impact in Mining Operations

Mining companies worldwide are already realizing tangible benefits from metal AM. Examples include:

-

Reduced lead times from months to days

-

Cost savings through digital spare parts

-

Improved reliability of critical components

-

Lower environmental impact

These results demonstrate that sustainability and profitability can go hand in hand.

The Future of Sustainable Mining Manufacturing

As metal additive manufacturing continues to evolve, its role in mining will expand further. Advances in process automation, material science, and digital workflows will make AM even more efficient, scalable, and cost-effective.

Mining companies that invest in AM today will gain long-term advantages in sustainability, resilience, and competitiveness.

Conclusion

Metal additive manufacturing is redefining sustainability and cost efficiency in the mining industry. By reducing waste, lowering costs, minimizing downtime, and enabling smarter design and production strategies, metal AM delivers measurable economic and environmental benefits.

For mining companies seeking to balance performance with responsibility, metal 3D printing offers a proven pathway toward a more sustainable and profitable future.